Manufactured Products &Services

Manufactured Products &Services

Grinding Services

Applicator Training

Hardsurfacing Overlays, Finished Parts

Manufacturing or hardsurfacing of wear components requires qualified applicators as well as products adapted to the application.

Our capabilities extend from hardsurfacing customer owned parts to providing finished parts based on your requirements.

Our manual application operation and our automated PTA equipment enable to apply a great diversity of harsurfacing or buildup products on parts of simple or complex geometry.

As an ISO 9001:2015 certified company, S.P.R.S. has qualified technicians on staff in order to ensure that you receive parts that not only conform to your specifications but will also provide maximum performance in service.

S.P.R.S. also assists in the development of wear parts adapted to specific wear problems and offers full manufacturing and grinding services.

Manufactured

Products

Chute Liners

Belt Cleaner Discs

Oil Press Auger Segments

Crushing Wheels

Pulley Cleaners & Holders

Flow REstrictors / Radial Bearings

Weld On Grouser Bars

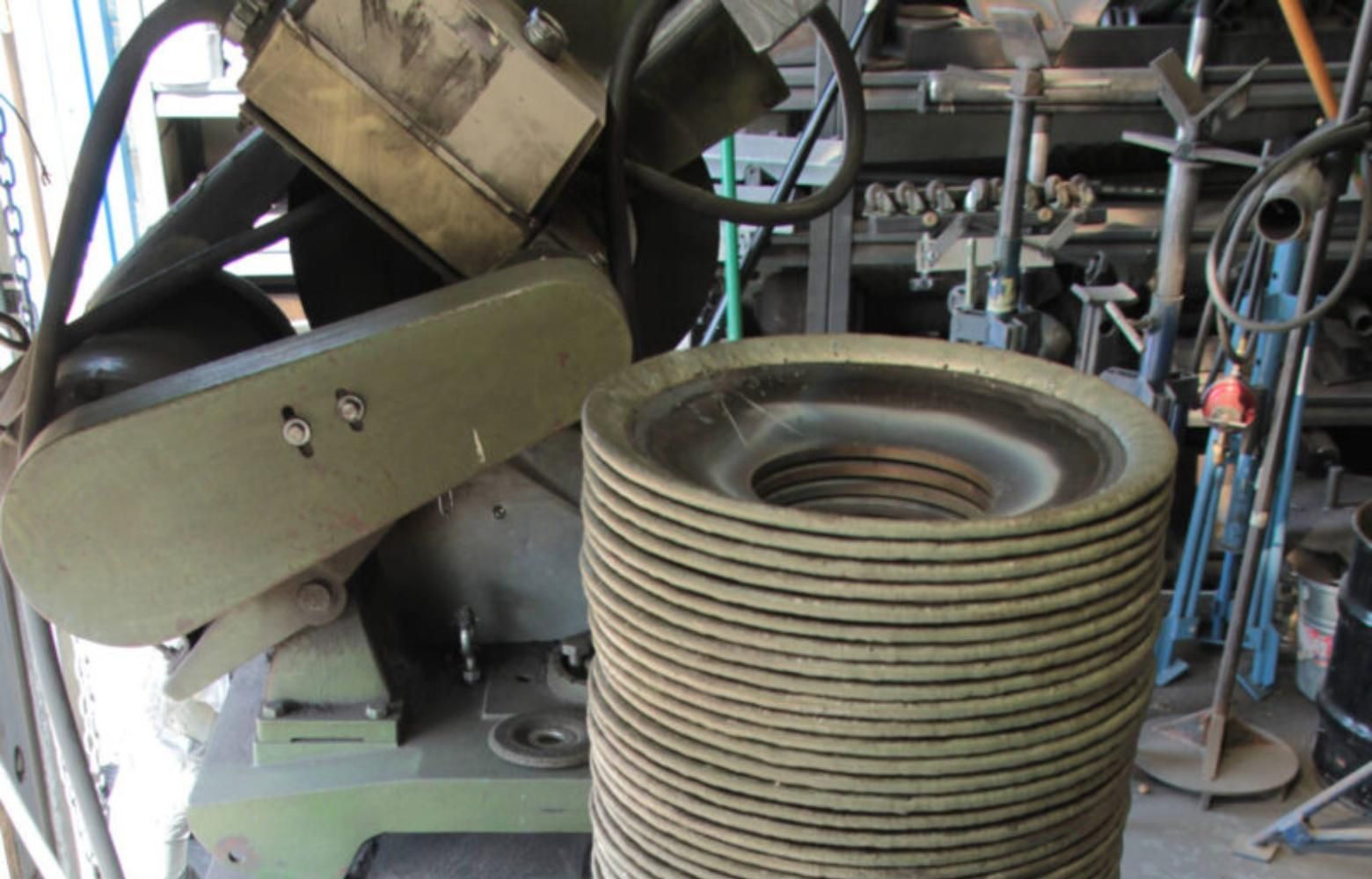

Belt Cleaner

Discs

The challenge was to select a pattern of the hardfacing which would provide a knife blade type of cleaning action, while having a minimal area of the belt subject to abrasion.

Several products and semi automatic application processes, including PTA and such, were considered.

It became quickly obvious that the most effective hardsurfacing product for this service was an oxytorch applied, Spherical tungsten carbide based product called TECHNOSPHERE.

This product enabled to apply coarse and very hard Spherical carbides, non aggressive for the belt. The oxytorch, low temperature, application process enabled to keep the original hardness of the carbides, contrarily to much hotter electric arc or plasma arc processes.

SPRS has manufactured these discs in Edmonton ever since.

Discs, as well as hub and shafts, are kept in inventory in Edmonton for immediate shipping. Complete assemblies of the cleaner hubs can also be provided.

Chute

Liners

- SPRS manufactures chute liners using Technodur® tungsten carbide overlay.

- These chute liners are designed for the extreme abrasion conditions that are seen in the oil sands.)

- The plates are built to our customers specifications and careful attention is taken to ensure that the final bolt pattern is maintained.

CRUSHING

WHEELS

- SPRS manufactures and hardsurfaces crushing wheels using Technodur® and Technosphere®.

- This particular pattern allows for clearing of the crushed material or seeds between the button like configuration.

- It can also be applied to roller or cone crushers.

- It can be rebuilt very easily and safely when worn.

OIL PRESS

AUGER SEGMENTS

- SPRS manufactures segments for oil presses and extrusion augers as per customer’s specific requirements.

- The segments are hardsurfaced using a combination of Technodur® and Technosphere® to obtain a balanced wear pattern.

- The rebuilding of segments is easy and very cost effective.

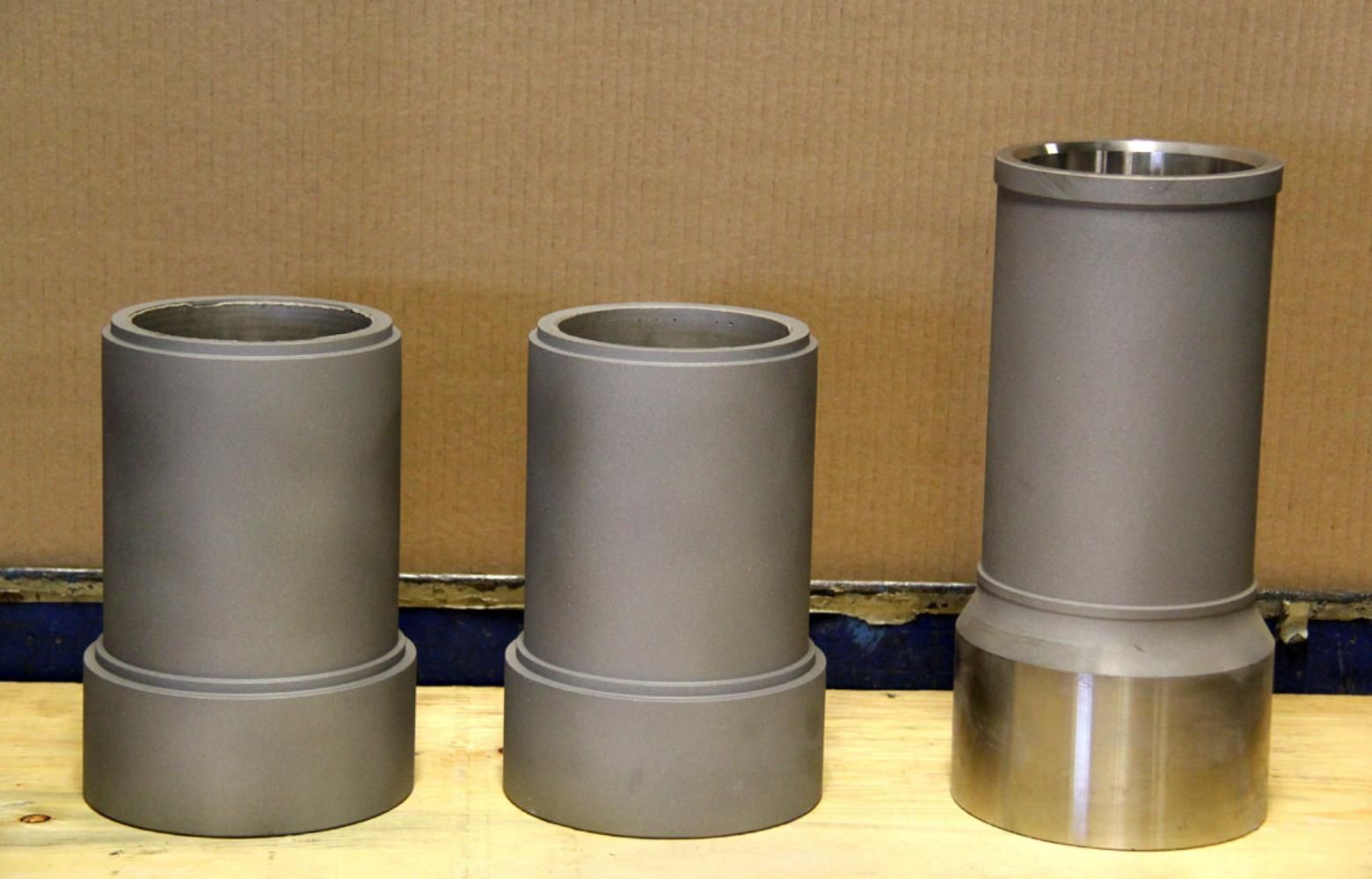

FLOW RESTRICTORS /

RADIAL BEARINGS

As per customer requirements parts can be supplied finished or hardsurfaced and ground to size for final machining. SPRS is able to hardsurface and grind a wide range of male and female restrictor parts.

Flow Restrictors after hardfacing and grinding to size (±0.0005”).

Finished parts after final machining.

PULLEY CLEANERS &

HOLDERS

SPRS PULLEY CLEANER KNIVES

These patented pulley cleaner knives have been designed specifically for oil sands operations. They are equally effective in summer and winter. They are currently the most effective tool available.

SPRS KNIFE HOLDERS

The exceptional long life of the PCK1125 knives requires knife holders specially reinforced at the base where the holder slides against the guide bars. Early wear of the base of the holder changes the angle of the knife to the surface of the pulley and seriously reduces the cleaning efficiency.

KNIVES AND KNIFE HOLDERS

These specially designed parts, used as a set, ensure that the knives work at their maximum efficiency for the best cleaning action on the pulley.

WELD ON

GROUSER BARS

S.P.R.S. manufactures and keeps in inventory various weld-on Grouser Bars.

These Grouser bars are hardsurfaced with 1/2″ nominal thickness of tungsten carbide product of exceptional resistance to abrasion and impact.

Standard stocked sizes include:

| Dimensions | Part Number | |

|---|---|---|

| Coated on top only: | 1.5″ high x 1″ wide x 8″ long | 8F-WB8TDGN |

| 1″ high x 1″ wide x 7.5″ long | 8F-GB7.5C | |

| 2″ high x 1.5″ wide x 11.5″ long | 8F-GB296C | |

| Coated on top and sides: | 6.5″ high x 2″ wide x 17″ long | 8F-SPLITWBC |

S.P.R.S. can manufacture custom sized Grouser Bars according to customer requirements.

These bars can be built up at site repair facilities to compensate for wear without compromising the integrity of the bar. This can provide significant cost savings in proper applications.

Grinding

Capabilities

Tos Hostivar

Schaudt

Norton

Grisetti

W&S

Cincinnati

Cincinnati Milacron

Cincinnati Milacron Heald 273A